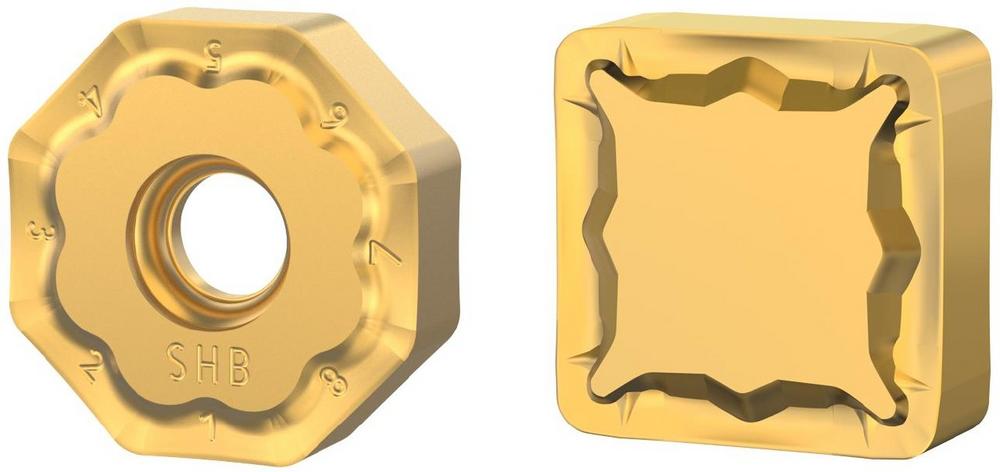

Cut longer with Kennametal’s KCK20B™ and KCKP10™ indexable milling grades

Breaking News:

Kathmandu Nepal

Freitag, Feb. 7, 2025

“The new grades feature High-Power Impulse Magnetron Sputtering (High-PIMS) technology that provides a smoother insert surface and optimal layer adhesion for less flank wear – one of the leading causes of insert failure,” says Gil Getz, Product Manager, Kennametal. He notes that the new coating technology also increases cutting edge strength. “The result is high-performance milling in a broad range of cast iron alloys, including grey cast iron, ductile cast iron, and compacted graphite cast iron.”

KCK20B and KCKP10 are suitable for wet or dry cuts. These include rotor hubs used in windmills, pump housings, steering knuckles and gear housings for heavy equipment, and automotive components like crankshafts and cylinder heads. While KCK20B delivers higher productivity in roughing and semi-finishing operations, KCKP10 is applicable for finishing operations, but also works exceptionally well when profiling and copy milling cast iron and steels up to 45HRC.

“For customers where high tooling cost and downtime associated with tool changes are especially important, KCK20B and KCKP10 grades promise to increase tool life tremendously,” says Getz. “And for those who wish to increase throughput, the new grades deliver there as well. Either way, it is a win-win for any shop machining cast iron.” Click here for more information: KCK20B™ & KCKP10™

With over 80 years as an industrial technology leader, Kennametal Inc. delivers productivity to customers through materials science, tooling and wear-resistant solutions. Customers across aerospace, earthworks, energy, general engineering and transportation turn to Kennametal to help them manufacture with precision and efficiency. Every day approximately 8,600 employees are helping customers in more than 60 countries stay competitive. Kennametal generated approximately $1.8 billion in revenues in fiscal 2021. Learn more at www.kennametal.com. Follow @Kennametal: Twitter, Instagram, Facebook, LinkedIn, and YouTube.

Kennametal Europe GmbH

Rheingoldstrasse 50

CH8212 Neuhausen am Rheinfall

Telefon: +41 (52) 6750100

http://www.kennametal.com

![]()