Safety in intra-logistics – modern and practical driver assistance systems for all forklift trucks (manufacturer-independent) and hazardous areas

Breaking News:

Kathmandu Nepal

Donnerstag, Apr. 24, 2025

Halle: 10 / Stand-Nr.: B05

In every company, there are many points and numerous hazardous situations in the material flow where not only people are at risk, but also accidents with considerable material damage occur.

This is where tbm hightech control GmbH from Munich specialises in technical safety and protective equipment for forklift trucks. Independent of the manufacturer, tbm equips all old and new forklift trucks with special sensor technology and electronics to prevent accidents and damage. Vision Zero has been an integral part of tbm for over 30 years. These assistance systems will be presented at LogiMAT 2025 in Hall 10, Stand xxxx.

Rear area warning system

New to the programme is the safest rear area warning system RRW-207 on the market. Performance level C. With modern radar technology, it prevents collisions with people or objects when reversing. Another special feature is its quick and easy installation. The installation of the optical/acoustic indicator display does not require any complex cable laying on the vehicle. It is simply installed in the driver’s cab. The connection to the evaluation electronics is made via WLAN. The simple installation is supported by the fact that only a single radar sensor is required for reversing monitoring.

Crossing protection

The GSA-107 hazard situation indicator was designed for this purpose. It is suspended at a height of around 4.5 m above a junction and detects vehicles or people approaching or leaving the junction. Without any vehicle equipment! In the event of a hazardous situation (e.g. a vehicle approaching the junction or a vehicle + person approaching the junction), the danger is indicated by a very large, bright, unmissable blue spot on the ground. This is generated by a powerful LED spot, which originates from crane technology. The alarm can be customised so that, for example, two arriving vehicles give a different warning signal than if a vehicle and a person drive/walk onto the junction at the same time. To prevent ‘alarms’ being triggered too frequently, people alone are categorised as ‘not a hazardous situation’, as too frequent alarms can also blunt the alert.

As a variant, the danger situation display is equipped with a powerful projector instead of the blue spotlight, which projects a giant traffic sign onto the ground. It has been proven that the active warning by means of a clear traffic sign is even more effective.

The hazard situation display is now also available integrated in a round mirror. This provides the familiar view upwards into a circular mirror

Collision protection against door damage

The NoColl Dome V2 on the vehicle prevents gate damage that occurs when the gate is not yet fully open or the vehicle is travelling too fast, or when the mast is simply extended too high and the vehicle does not fit through the gate. In this situation, the Dome V2 brakes the vehicle in front of the door until the pole is lowered or the door is ‘fully’ open. Only then can the vehicle continue travelling at either reduced or full speed.

Collision protection in zones and areas

Here too, the NoColl Dome V2 ensures that the adapted speed is maintained after entering this area or the defined zone. This is how modern accident and labour protection works, taking into account economic efficiency in logistics.

Collision protection between vehicles

With the NoColl Dome V3, active collision protection is achieved, which automatically reduces the speed when two vehicles meet on a traffic route. This may be because an adapted speed increases safety from the outset, or because it is necessary in wide aisles between racks if the width of the traffic route requires it. The speed is only reduced until the vehicles have passed each other. From then on, you can drive at your usual speed without being affected.

With many other features, such as

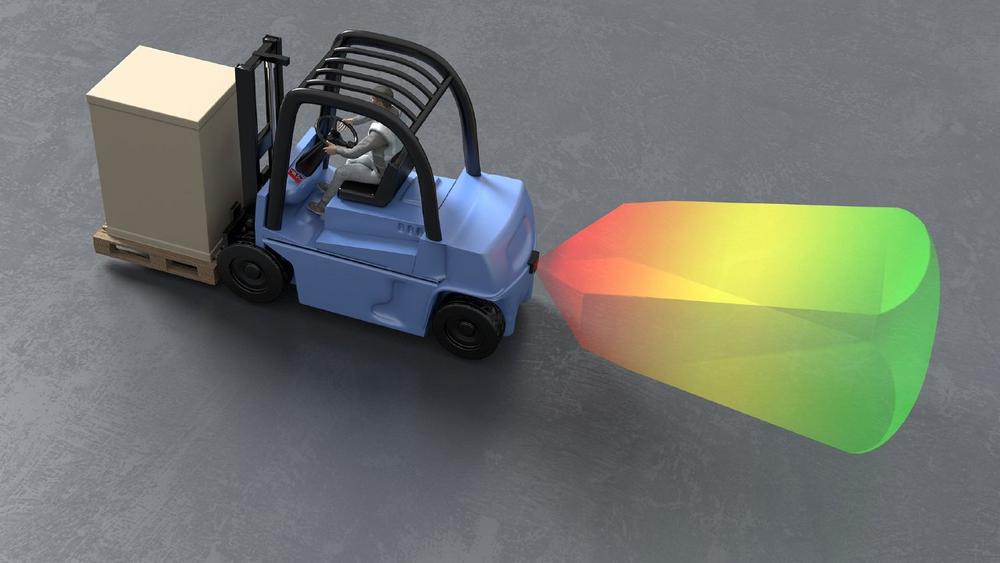

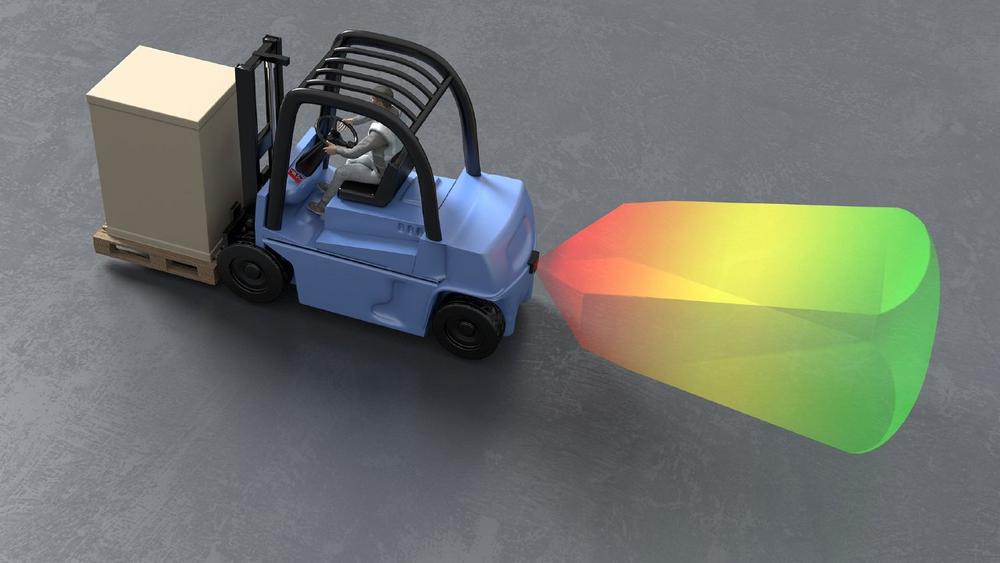

– the forklift Aura-107, a transponder system that protects people around the forklift truck

– the IOG-207 in-door/out-door speed controller, which regulates the permitted speed in indoor and outdoor areas

– the SafetyDoorLight LDS-107, which protects people at doors

– and much more

tbm fulfils customer requirements in terms of safety in logistics. These will be presented at LogiMAT 2025 in Hall 10 Stand B 05.

tbm hightech control GmbH

Karl-Hammerschmidt-Str. 32

85609 Aschheim b. München

Telefon: +49 (89) 6700360

Telefax: +49 (89) 6379172

http://www.tbm.biz

![]()