Production technology for battery cells

Breaking News:

Kathmandu Nepal

Samstag, Apr. 19, 2025

In September 2022, Dürr AG, GROB-WERKE GmbH & Co. KG, and Manz AG entered into a strategic cooperation for the joint acquisition and processing of projects to equip complete battery factories. Even after the withdrawal of Manz, the goal of the partnership remains to jointly establish itself as a system provider of battery production systems in Europe and North America. This offers customers a high-performance alternative to the equipment suppliers that have mostly come from Asia to date.

Last year, Dürr and GROB expanded their machine and system portfolios for the production of battery cells and made them more efficient. Process steps previously covered by Manz can be taken over by the two remaining partners.

The strategic cooperation focuses on the automotive sector and the market for stationary battery storage systems, which are experiencing a significant increase in demand. Stationary storage systems absorb surplus energy from solar and wind power so that fluctuations in the electricity supply can be balanced out. They also serve as home storage solutions for solar power from private systems.

Although electromobility is currently progressing more slowly than expected, it is causing demand for battery production technology to rise sharply. Several battery and car manufacturers in Europe are therefore investing in battery factories. They are building up their own production capacities instead of buying battery cells almost exclusively from Asia, as has been the case to date.

Lower consumption of energy and raw materials

The cooperation between Dürr and GROB aims to minimize energy consumption in cell production and increase the quality of the battery cells produced. “We achieve this, on the one hand, through the high availability of our automated machines and systems and, on the other, through a consistent digitalization concept that allows our customers to monitor all production steps,” explains Dr. Jochen Weyrauch, CEO of Dürr AG.

In December, Dürr received a major order from the Italian battery manufacturer FIB and will install a turnkey system for electrode coating at the plant in Teverola near Naples. The plant is designed for the production of lithium-ion battery cells with a total output of 8 gigawatt hours per year.

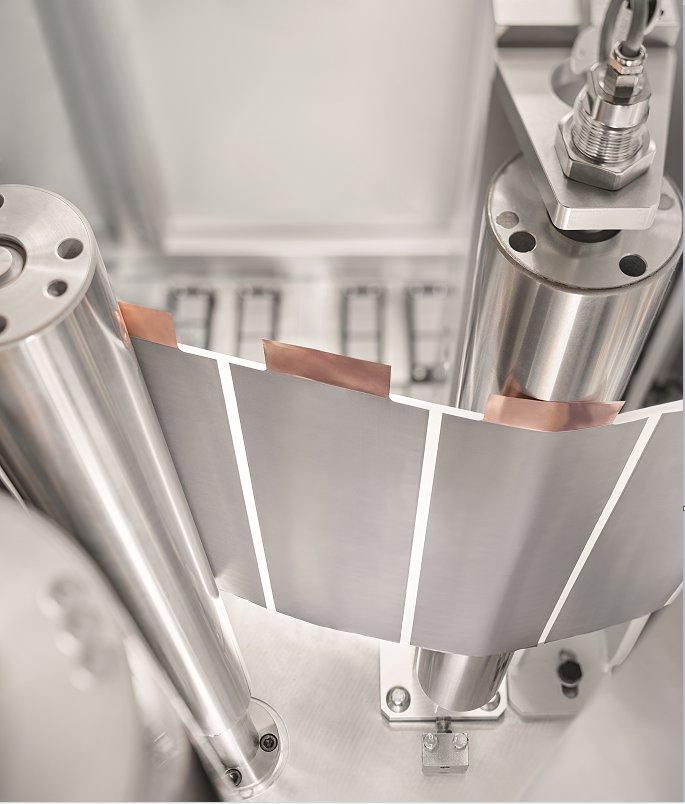

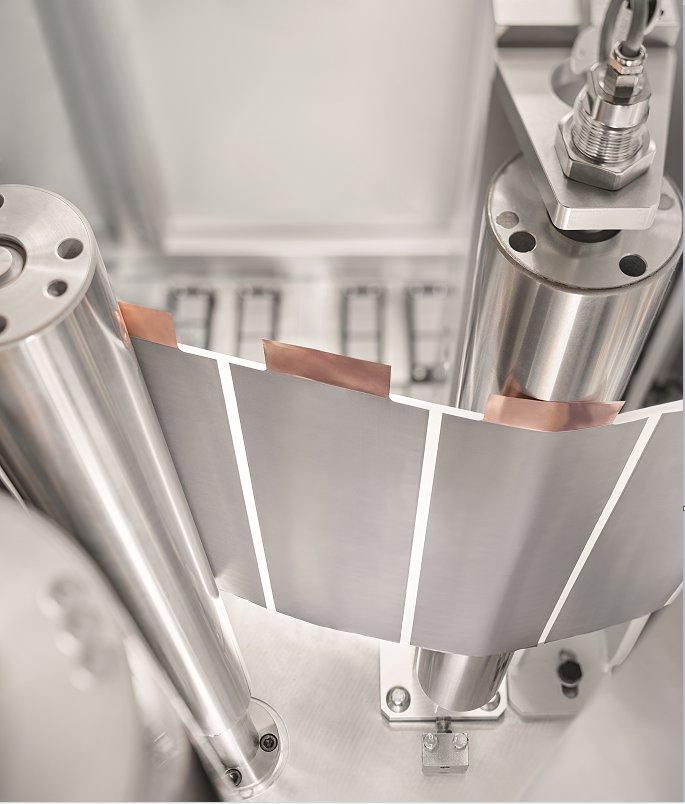

The cooperation partners are already implementing their first projects together. For example, Dürr and GROB are supplying a European cell manufacturer with machines for the production of high-performance battery cells. Dürr is installing systems for the conventional wet coating of electrodes, which corresponds to the current state of the art, and is planning a pilot system for efficient and sustainable dry coating. GROB supplies the complete cell assembly based on innovative lamination technology, which enables a significant increase in production speed and therefore low manufacturing costs.

“The Dürr-GROB cooperation stands for the highest quality and reliability in mechanical and plant engineering. Our systems verifiably meet the requirements and specifications of battery cell producers worldwide,” says German Wankmiller, CEO of the GROB Group. GROB is working with several well-known cell manufacturers on the development of production systems.

Dürr and GROB are exhibiting together at the Battery Shows in Europe, North America, and India.

For almost 100 years, GROB has been a family-owned company operating worldwide in the development and manufacture of systems and machine tools. Its customers include the most well-known automotive manufacturers, their suppliers and companies in a wide range of industries. With production plants in Mindelheim (Germany), Bluffton, Ohio (USA), São Paulo (Brazil), Dalian (China), Pianezza (Italy) and Bangalore (India) as well as worldwide service and sales branches, GROB is internationally established. With 9,000 employees, the GROB Group generates a turnover of 1.8 billion euros worldwide (FY 23/24).

The portfolio ranges from universal machining centers to highly complex manufacturing systems with their own automation, as well as manual assembly stations and fully automated assembly lines. Furthermore, the product range includes production systems for electric motors and assembly systems for battery and fuel cell technology. The company also develops its own solutions for conventional machining of turbine housings and the task of processing structural and chassis components. With GROB-NET4Industry, the software developed in-house for digitizing and networking production processes, production processes can be digitally and transparently displayed.

GROB-WERKE GmbH & Co. KG

Industriestr. 4

87719 Mindelheim

Telefon: +49 (8261) 996-0

Telefax: +49 (8261) 996-268

http://www.grob.de

![]()