New outfit for the EPIC® rectangular connectors

Breaking News:

Kathmandu Nepal

Donnerstag, Nov 7, 2024

The previous design of the EPIC® rectangular connector housings of the HB and HA series dates back to the 60s – basic geometry and therefore quite angular. The previous supply chains and tool ensured a complex production process. “With a whole package of measures, we want to impress our customers once again with EPIC® and we are confident that in future they will once again order everything from a single source – not just cables, but also the right connectors,” says Martin Hoffmann Vicente, responsible Product Manager at LAPP.

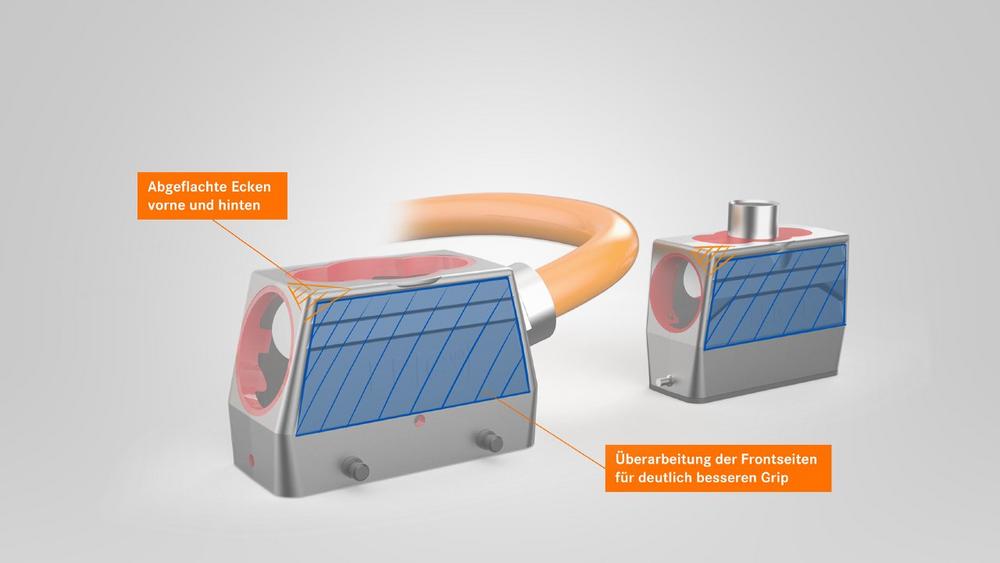

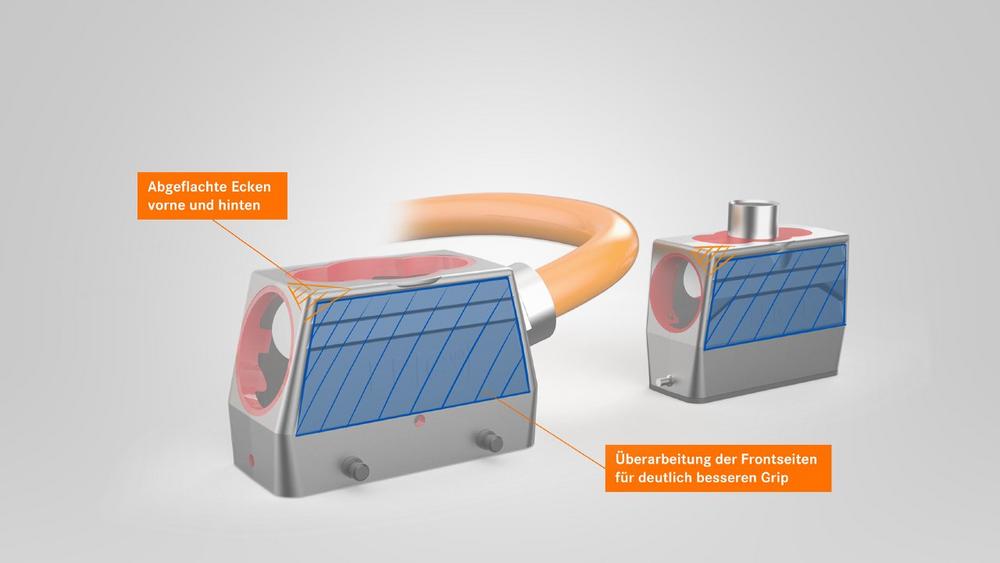

Improved haptics with ribs

First, the design was refreshed together with an industrial designer and LAPP’s internal development department. The front and back corners were flattened and deeper ribs were drawn at the front sides. This makes it easier to handle the rectangular connectors and prevents them from slipping out of their hands during assembly if the fitter may have oily fingers. Instead of the EPIC® logo, the LAPP logo is now applied to both front sides in order to better represent the LAPP umbrella brand in the industry. The functional surfaces – the holes for inserting the cables and the bolts – remain unchanged, as does the powder-coated die-cast aluminium material.

Optimised supply chains and new tool

The supply chains have also been optimised. Previously, there were several different suppliers for raw sleeves, coatings and threads. Now, everything from a single source is delivered to LAPP for final production, where only the customised cable entries are milled and bolts set.

For this final production process, the plant in Stuttgart procured new tools that work even faster, more flexibly and therefore more efficiently. "Production in Stuttgart ensures quality at all times", emphasises Martin Hoffmann Vicente. Of course, the redesigned EPIC® rectangular connector housing is also compatible with other manufacturers and can thus fully replace older applications and competitor products.

Market introduction in the summer

LAPP will be launching the first HB-16 EPIC® rectangular connector housings in industry from the summer. The entire HB and HA series will be converted to the new design by the end of 2024. At the same time, LAPP is planning to revise its portfolio. This means that collars will no longer be glued in the future, but will be provided separately as accessories. This gives customers more flexibility.

Headquartered in Stuttgart, Germany, LAPP is a leading supplier of integrated solutions and branded products in the field of cable and connection technology. The company’s portfolio includes standard and highly flexible cables, industrial connectors and screw technology, customised system solutions, automation technology and robotics solutions for the intelligent factory of the future, as well as technical accessories. LAPP’s core market is the industrial machinery and plant engineering sector. Other key markets are in the food industry, logistics, as well as the energy and the mobility sector.

The company was founded in 1959 and is still fully owned by the founding family to this day. In the 2022/23 financial year, it generated a consolidated turnover of EUR 1.92 million. LAPP currently employs approximately 5,551 people across the world, produces at 21 international sites and has its own sales companies in 36 countries. Thanks to additional cooperation with business partners, the company has a total of around 100 representative offices worldwide.

U.I. Lapp GmbH

Schulze-Delitzsch-Str. 25

70565 Stuttgart

Telefon: +49 (711) 7838-01

Telefax: +49 (711) 78382640

http://www.lapp.com

![]()