A New Level of Transparency

Breaking News:

Kathmandu Nepal

Mittwoch, Apr. 23, 2025

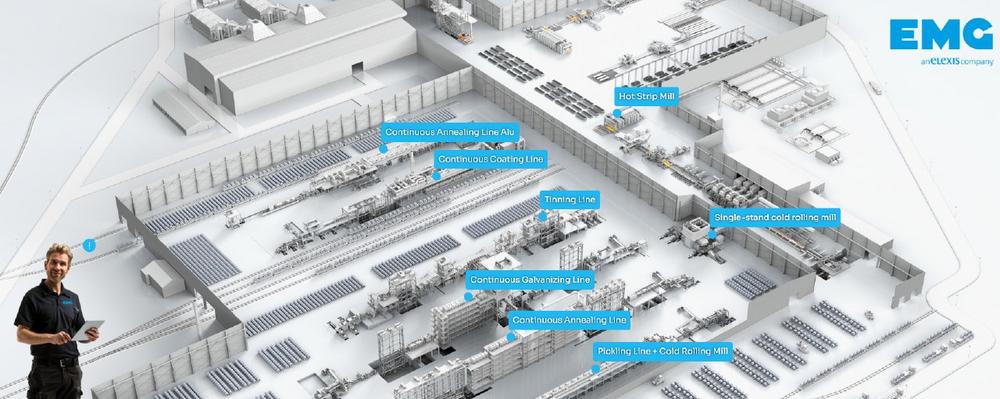

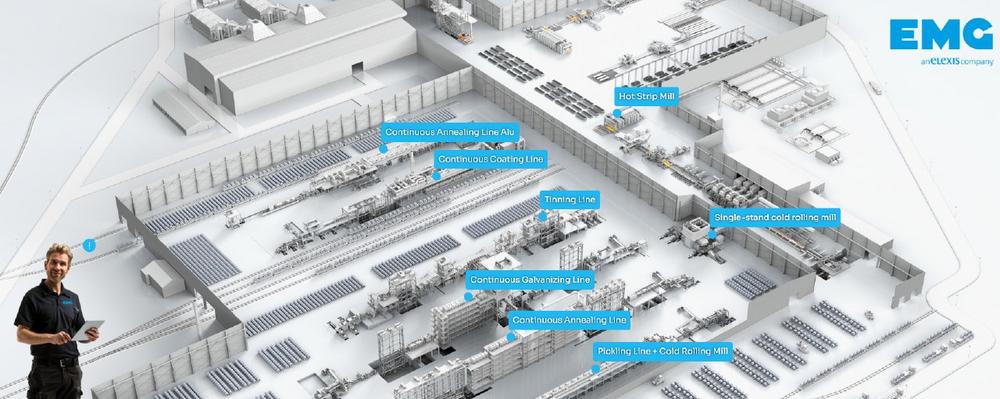

But as the breadth and complexity of EMG’s product landscape has grown, so has the challenge: How can potential customers or partners quickly grasp where and how these solutions fit into their specific process lines? With well over 100 possible installation locations across various line types and process sections, it’s easy to lose the overview.

To address this challenge, EMG has launched a digital process line visualisation tool on its website – a highly intuitive and interactive resource for anyone seeking clarity, insight, and product information.

Explore the EMG Digital Process Line →

From Overview to Detail: Navigating Process Lines Digitally

The new online visualisation starts with a macro-level view: the user selects a specific line type, such as a continuous galvanizing line, continuous coating line, or cold rolling mill. With a single click, the viewer zooms into a detailed digital representation of the line layout, clearly showing where individual EMG systems are typically installed.

Each possible installation location is marked and clickable. Whether it’s a sensor measuring strip width after the uncoiler, or a strip guiding system at the strip accumulator – every element is anchored within its real context.

This structure reflects the real-world complexity of these lines while offering a streamlined path to the relevant information. By focusing on each line section, users not only understand where a product is installed, but also why it’s needed and how it contributes to the process.

Deeper Insights at Every Level – Down to the Last Detail

What truly sets EMG’s visualisation apart is its layered depth. After selecting an installation point, users are taken to the products used at that position. Each product is presented with a high-resolution, rotatable 3D model, offering a realistic impression of the system’s form and look.

From there, technical specifications, typical application scenarios, customer benefits, product brochures, and direct links to EMG’s product website are only one click away. As an example, users examining the strip width measurement after the uncoiler can compare solutions such as the EMG BREIMO or EMG iCAM®, and view both hardware and feature highlights instantly.

The system also offers a seamless connection to EMG’s service infrastructure. On every process line overview, users can access relevant links to service offerings including repairs, spare parts, retrofits, and maintenance. This makes the tool not only useful for engineering and quality management but also highly relevant for service teams and plant operators.

A Tool for Experts- And Those Who Want to Become One

With this new digital platform, EMG combines its decades of experience with modern visualisation technology to provide a unique user experience. The tool is especially valuable for production engineers, maintenance personnel, and quality management professionals looking for fast, reliable insights into how EMG solutions can fit into their specific process environments.

Whether you’re exploring new equipment for a plant upgrade, planning a retrofit, or simply comparing technologies – this tool enables you to dive as deep as you like. From high-level line overviews down to interactive 3D product visualisations, the structure offers both orientation and detail, tailored to your needs.

Discover the product landscape of EMG and unlock the full potential of your process line.

Start your journey here:

elexis AG

Industriestr. 1

57482 Wenden

Telefon: +49 (2762) 612-130

Telefax: +49 (2762) 612-135

http://www.elexis.group

![]()