SKZ develops innovative leak test

Breaking News:

Kathmandu Nepal

Dienstag, Apr. 29, 2025

Leak testing for all materials and industries

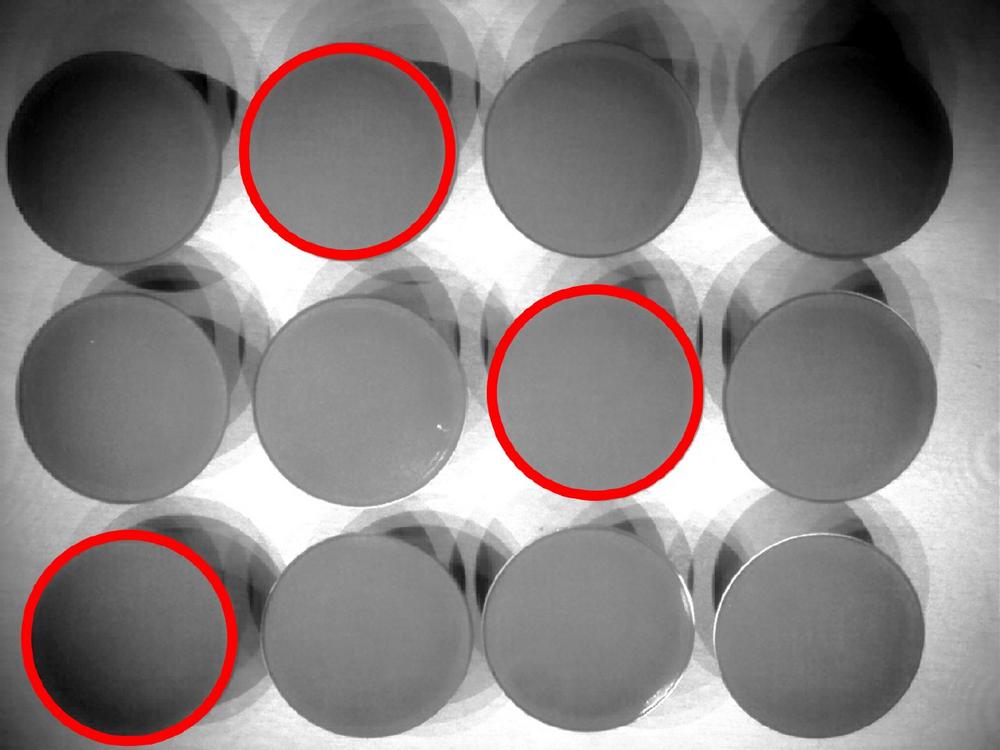

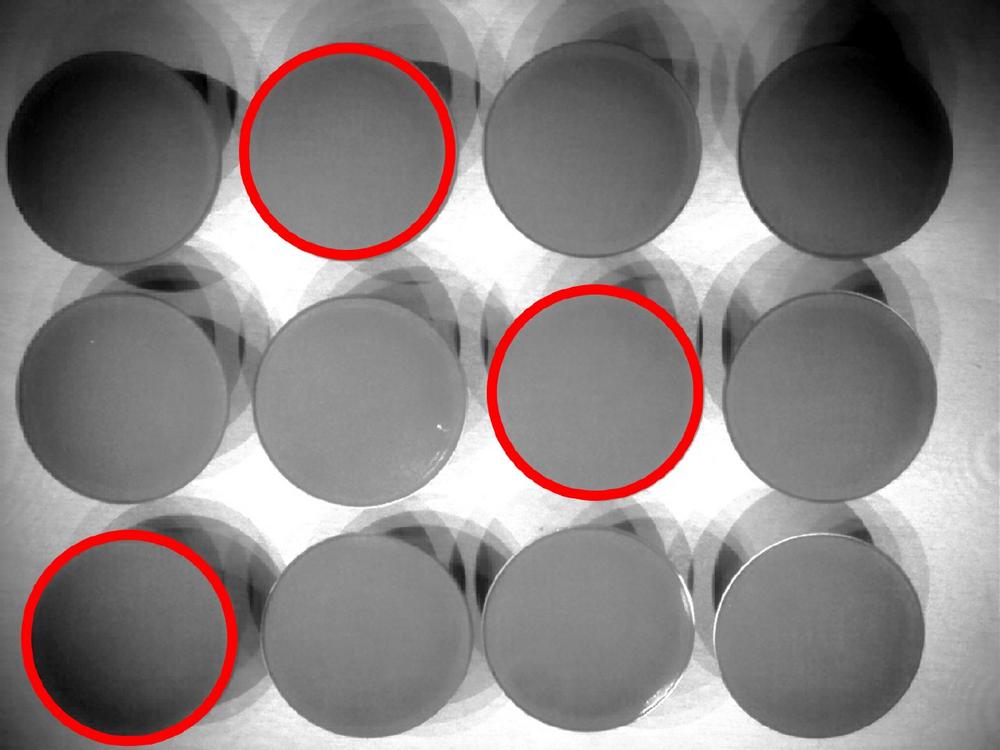

Whether glass, plastic or metal – the innovative measuring system tests all material combinations with maximum precision and without coloration restrictions. This makes it particularly suitable for sectors in which leak-proof packaging is essential, such as the food, medical and cosmetics industries. The smallest leaks can lead to premature spoilage, customer dissatisfaction or even health risks. The new inspection system offers a fast, reliable and cost-effective solution.

100% inline measurement for maximum quality assurance

Short measuring times and non-contact measurement enable 100% inline measurement. This ensures clear traceability, while at the same time providing objective, constant and low-staff testing.

"Thanks to the complete leak test, faults in production can be detected and rectified at an early stage, preventing rejects or even complaints. This reduces costs and makes a significant contribution to sustainable production and consumption," explains Luis Wachter, group leader for non-destructive testing at SKZ and co-responsible for the development of the measurement technology.

Fast, mobile and efficient

In contrast to conventional methods such as water bath, pressure or test gas testing, which are often time-consuming and cost-intensive, the new measuring system enables immediate and non-destructive analysis. Thanks to its compact design, it is mobile and can be easily integrated into existing production processes.

The SKZ is climate protection company and a member of the Zuse Association. This is an association of independent, industry-related research institutions that pursue the goal of improving the performance and competitiveness of industry, especially SMEs, through innovation and networking.

FSKZ e. V.

Friedrich-Bergius-Ring 22

97076 Würzburg

Telefon: +49 931 4104-0

https://www.skz.de

![]()